On the 7th March we held our first L2D demonstration courtesy of AHDB and Dunbia Sawley, it was a practical and educational event which allowed members to handle live animals and make assessment of fat cover, conformation using the EUROP grid and carcase weight.

Sue and Steve Powdrill AHDB assessing one of the Charolais cross cattle for finish

We then saw the same animals on the hook in the chillers with the actual classification, so we could compare our assessments made whilst the animals were alive.

Assessing the carcase against the live assessment with David Eden from MLCSL.

After reassessing the carcase’s we were shown the cutting room where all the meat is packed and processed for several different retailers, we then walked the line starting at the stunning box and observed all the operation right through to the independent classification carried out by MLCSL and fridges where the carcases are hung, there was also plenty of opportunity to discuss various market requirements, factors affecting killing out percentages and dressing specifications too.

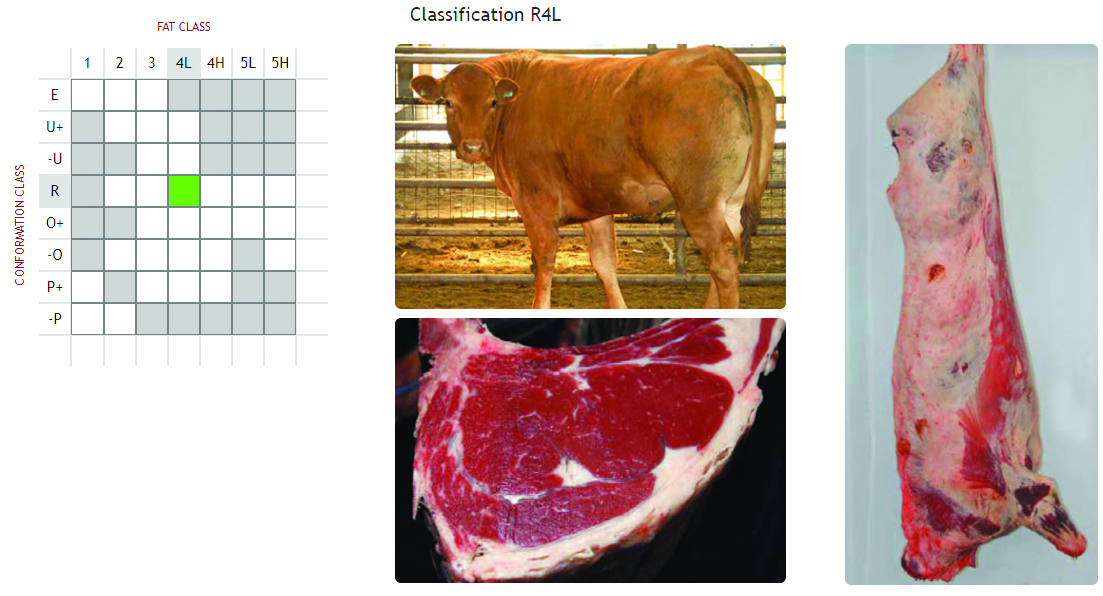

We discussed the EUROP grids advantages, disadvantages and interestingly an R4L now suits approximately 85% of the markets needs, with 56% of the carcase being minced and a higher percentage of the rounds minced.

One of the key messages that came out of the day was that we need to keep our focus on the width, depth and length of loin the high value cuts, its far more important than producing animals with poor loins and large rounds with the rounds being of less value and possibly minced

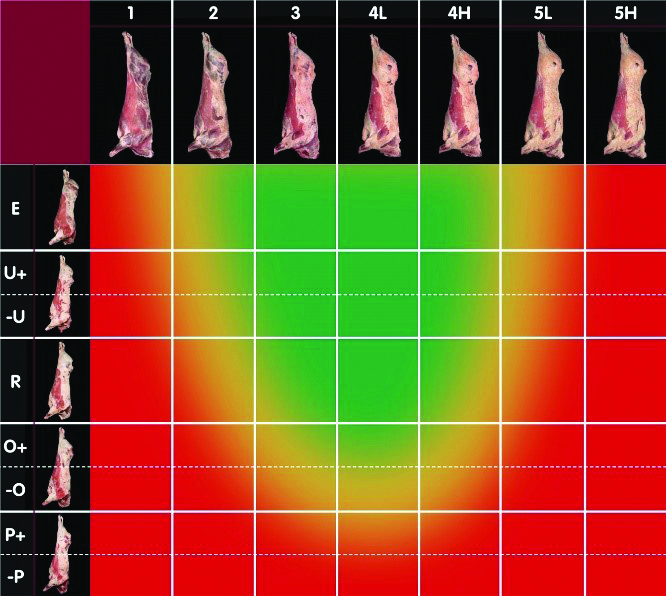

Some of the key slides from the day

Prime beef selection | Carcase classification grid

The green area is the key target area for demand with the amber and especially the red less so.

Prime beef selection | Understanding cattle and carcases

An R4L now suits 85% of the markets needs

Finishing cattle

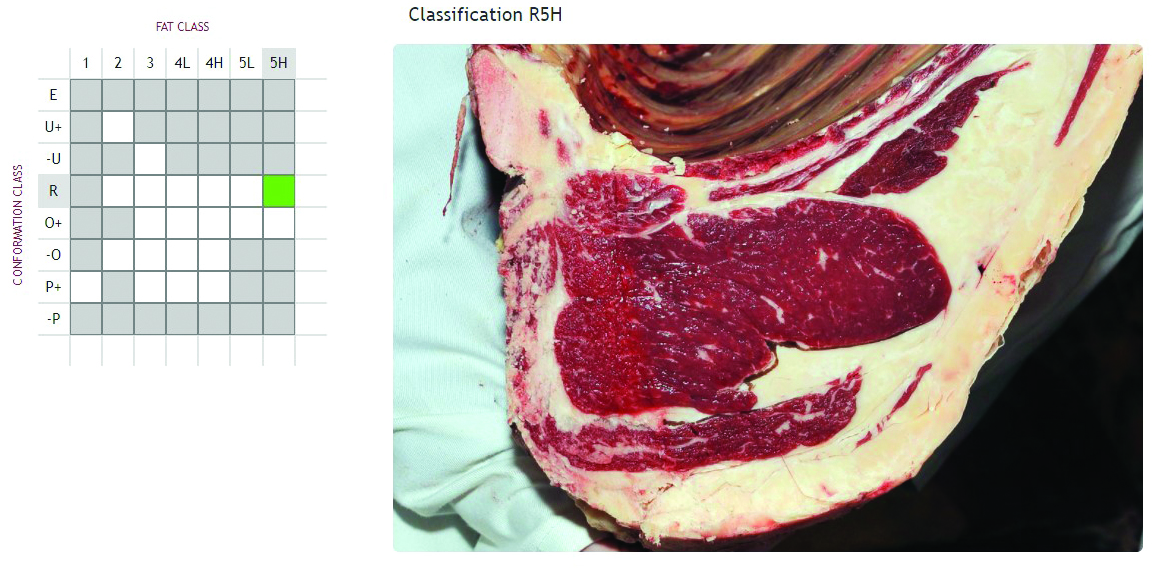

Finishing cattle and the cost to the industry for having over fat cattle, it’s not only an extra cost to the farmers producing fat cattle (and getting penalised for its classification) but a cost to the abattoirs who then must trim the fat off and in some cases valuable joints are having to be minced

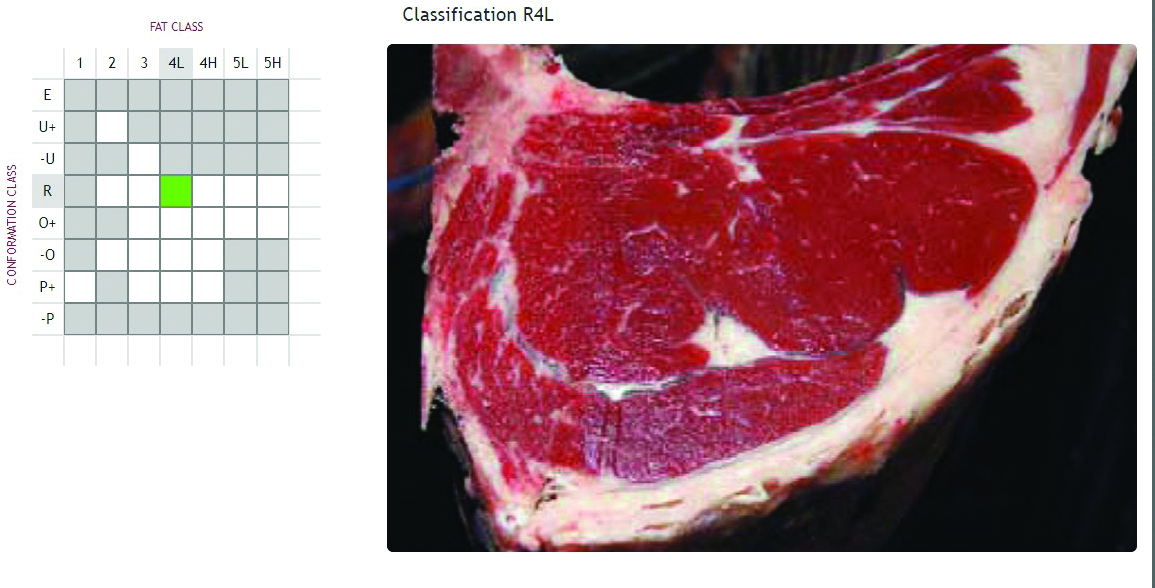

On the pictures below, you can see the difference between the two classifications of rib eye with the 5H showing an excess in the Subcutaneous, intramuscular and intermuscular fat levels

Classification R4L

Classification R5H

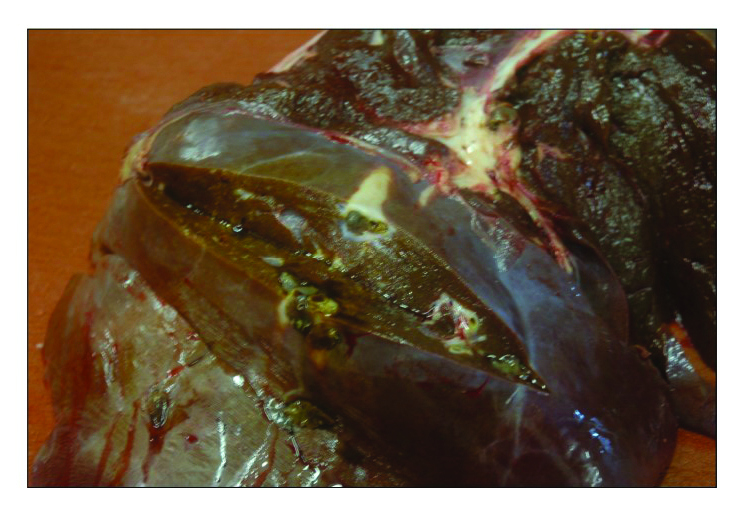

Liver Fluke

One of the things we discussed was the effect of liver fluke to the industry and here we have an infected condemned liver which is full of fluke this not only hits the daily live weight gains of the animals but costs the industry many £1000’s in livers that are not fit to use.

Injection damage

This was another issue which is costing the industry a lot of money here are two silversides which have been damaged from injecting in the wrong area with dirty needles, the conclusion was its better to inject into the neck muscles with new needles from an animal welfare point and spoiling more expensive cuts of meat.

It was an excellent day both in the classroom and in the abattoir Steve and David from AHDB are good down to earth people who understand the industry and its always great to learn something about the industry we all work in.

A big thankyou to Dunbia Sawley for hosting the event and providing a great buffet dinner.

If you fancy coming along, please give the office a call and we’ll put you on the waitinglist.

Photos courtesy of AHDB

Categories: Commercial, News

Dungannon Charolais sell to 4,500gns » « Mclaren races to 6,500gns at Welshpool